Real Life Examples of How AcornVac, Inc. Helps Facilities Address Construction, Security & Sanitation Challenges

AcornVac® vacuum plumbing systems can provide control, security, and safety to state correctional facilities, alleviate the hazards associated with biochemical waste from medical institutions, and provide just about any organization a way to save water, ensure cleaner facilities, accommodate restrictive site and structural concerns and provide flexibility and security that traditional plumbing systems do not.

Check out the case studies below for real-world examples and see how vacuum plumbing might be able to help you!

GROCERY, RETAIL AND RESTAURANTS

Case Study - Amazon Warehouse San Bernardino, CA

After Amazon opened its San Bernardino fulfillment center, they saw a need to include a grocery fulfillment department. Dry goods could be stored easily, but perishables, dairy, and fresh produce required refrigeration.

Faced with the expensive challenge of trenching through a prohibitively thick slab with structural steel throughout, the designers decided to utilize an AcornVac vacuum plumbing system, an overhead plumbing solution that avoided floor cutting altogether.

Sign Up to Receive Our Newest Case Studies and Newsletter!

Case Study - Mission Yogurt, San Jose International Airport

Mission Yogurt selected an AcornVac vacuum plumbing system for their new food court in the Norman Y. Mineta San Jose International Airport because it solved a construction stopping problem. The AcornVac system guaranteed plumbing leaks from food court waste lines would not occur, let alone penetrate the baggage handling area below the food court.

Case Study - Pier A Harbor House, NYC

When New York City restaurant and development company, HPH chose the historic Pier A in New York's Battery Park as the location for their new entertainment destination they had one challenge to overcome. All the new plumbing would have to be contained within the building - a building that extended 400 feet over the Hudson River.

Case Study - Guy Fieri’s Vegas Kitchen and Bar

While the location selected for Guy Fieri’s Vegas Kitchen and Bar was a restaurateur’s dream, the construction challenges were an architect’s nightmare. See how vacuum plumbing solved the problem!

Other Projects

Commercial Retail Remodel

"The AcornVac System provided a healthy store environment for employees and guests during the construction process. The system eliminates the saw cutting of the concrete throughout the store floor which would have produced a great deal of dust and residue - no matter how carefully you tarp off the area. With the AcornVac System, we reduced the amount of construction waste, tile, concrete, carpeting, etc. while being environmentally friendly."

Trader Joe’s

"With our exposed concrete floor, vacuum technology allows Trader Joe’s the flexibility to move and add additional cases without saw cutting. This allows us to keep a consistent looking floor free of patches and trench lines."

MANUFACTURING AND INDUSTRIAL

Case Study - Tesla GigaFactory

Just to the east of Reno Nevada sits a newly constructed, clean manufacturing facility of enormous proportions. Within the walls of this building are miles of vacuum waste plumbing, an advanced alternative to gravity plumbing that offers Tesla unrivaled flexibility and adaptability to meet ever-changing infrastructure demands.

Other Projects

Capital Engineering Consultants

"AcornVac was very helpful throughout the design process, providing the necessary design and specification input. The installation of the system went very smoothly."

OFFICE

Case Study - 400 Westlake

AcornVac® Vacuum Plumbing Systems were chosen for an office renovation at 400 Westlake in Seattle, Washington. The renovation would preserve the building and had a focus on sustainability. Holaday-Parks, Mechanical and Plumbing Engineer on the project, chose AcornVac primarily because of their water saving potential, since AcornVac’s toilets require less than .5 gallons of water per flush.

PRISONS, JAILS AND CORRECTIONAL FACILITIES

Case Study - Salinas Valley State Prison

At the Salinas Valley State Prison in Central California, inmates had taken a liking to passing contraband through outdated gravity plumbing systems, occasionally causing disturbances with incessant flushes and clogs.

This case study will help you learn more about how the state-of-the-art AcornVac vacuum plumbing system helped decrease the flow of contraband nearly eliminate plumbing blockages.

"We have hardly had any costs in maintenance. If something plugs up, it’s right there at the fixture, making it easy to isolate and fix. The vacuum system is better because everything must pass a valve, and once it does, it can’t be retrieved at the fixture."

Case Study - Western Virginia Regional Jail

Nestled in the Shenandoah Valley, the Western Virginia Regional Jail in Salem, Va., is considered one of the safest and most cost-efficient correctional institutions of its kind. In addition to keeping our prisons cleaner and safer, the cutting-edge "half-gallon flush" from an AcornVac system has helped to decrease water usage in facilities around the country.

Take a look at this case study to learn more about the sustainability benefits of vacuum plumbing.

"AcornVac is a powerful money saver. For starters, we cut the Authority’s waste cost by $200,000 a year. We saved $400,000 upfront in domestic water connect fees because AcornVac’s smaller piping network simplifies everything, and we drastically reduced how the inmates control the jail by eliminating clogged pipes."

"AcornVac provided collaboration, document review, and analytical support during the entire design process. They were very responsive to the project's unique nature and design schedule."

Case Study - Amherst Country Adult Detention Center

Case studies are often completed just after a project is completed— when the client is still in the honeymoon phase, but wouldn’t you like to know how the client is faring after several years? We decided to go back to Amherst Country Adult Detention Center and check in on how their AcornVac system has been working for them over the past six years. We caught up with a few employees who were there when the Center was being built, as well as some maintenance crew members who came on board relatively recently to find out how the system is holding up.

Other Projects

California Department of Corrections

"AcornVac in combination with other conservation efforts throughout the new facility contributes to a reduction in potable water use by a remarkable 56% and lowered sewage conveyance by nearly 70% through a state of the art vacuum plumbing system."

HEALTHCARE AND MEDICAL RESEARCH FACILITIES

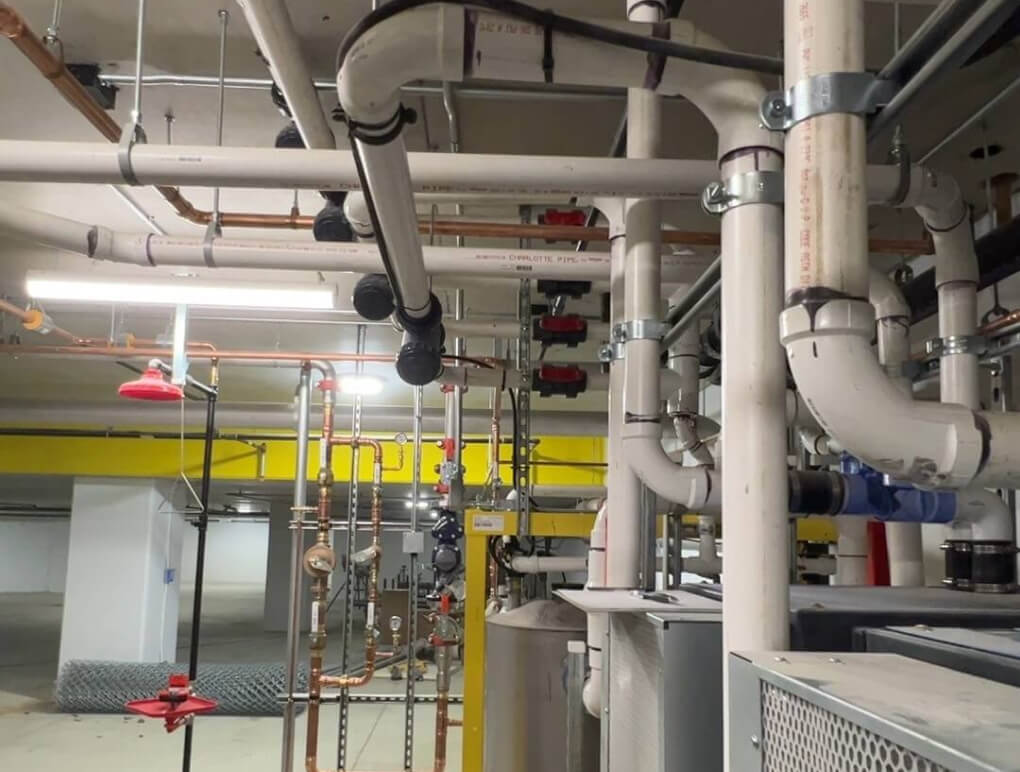

Case Study - The Center for Medical Science

If released into the atmosphere, biochemical excretions quite possibly pose the greatest threat to our society. We are well aware of the potential dangers of biochemical and medical engineering and has offered its services to help eliminate this hazard.

The Center for Medical Science (images) in Albany, N.Y., recognized our dedication to safety. This case study will provide insight on how an AcornVac system can alleviate common concerns in the medical and healthcare communities.

"Essentially, AcornVac made it possible to do our project in confined space for a reasonable sum, and master control over waste water from cradle to grave - an impossibility with gravity plumbing... Ninety-five percent of the work was done right within the space. A nice, neat package."

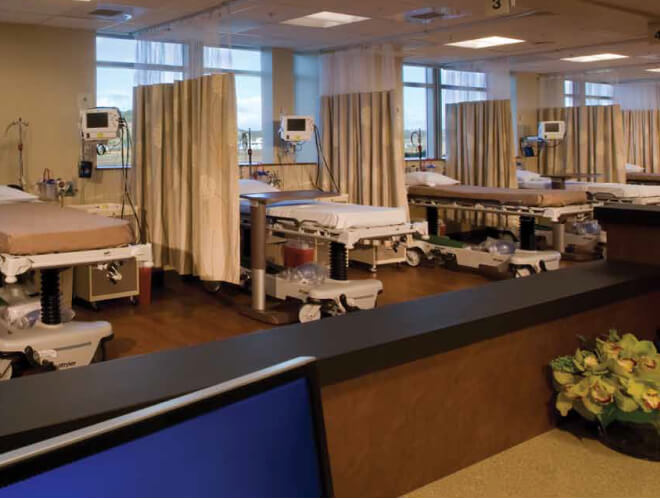

Case Study - The Polyclinic, Seattle

The Polyclinic, a physician-owned, multi-specialty medical group serving the greater Seattle area, have committed themselves to delivering personalized healthcare. With that mission in mind, they identified a building perfectly located to provide care to the population they intended to serve. While the location was ideal, the building’s plumbing infrastructure was not. The clinic would require sinks in every exam room and bathrooms throughout a building with no means to drain them.

On the upside, the building was available at a much lower lease rate. Being physician-owned and multi-specialty also means an ongoing need for regular but costly reconfiguration of their facilities as doctors’ requests and needs change, making the lower monthly lease rate particularly attractive. Floor cutting and plumbing work would not only disrupt the clinic, but also the space and operation of the tenant below.

HISTORIC BUILDINGS

Case Study - Holaday-Parks

To renovate an historic building while simultaneously seeking to reach new heights in sustainability, Hola- day-Parks installed a water-saving vacuum plumbing system from AcornVac, a Morris Group International® brand. The AcornVac® system was among the solu- tions that earned the building recognition as one of the most environmentally friendly office spaces of its size worldwide. It also eliminates the need for costly trenching or core drilling.

Once a two-story building, 400 Westlake now stands tall as a 15-story office building, encompassing 180,000 square feet of office space and ground-floor retail. Situated in the vibrant South Lake Union district of Seattle, WA, it has the distinction of being part of Seattle’s Living Building Pilot Program, earning the esteemed Living Building Challenge’s Petal Certifica- tions in the areas of energy, beauty, and place.